Room silencing, vibration reduction, vibration and noise measurements

Room silencing, vibration reduction, vibration and noise measurements

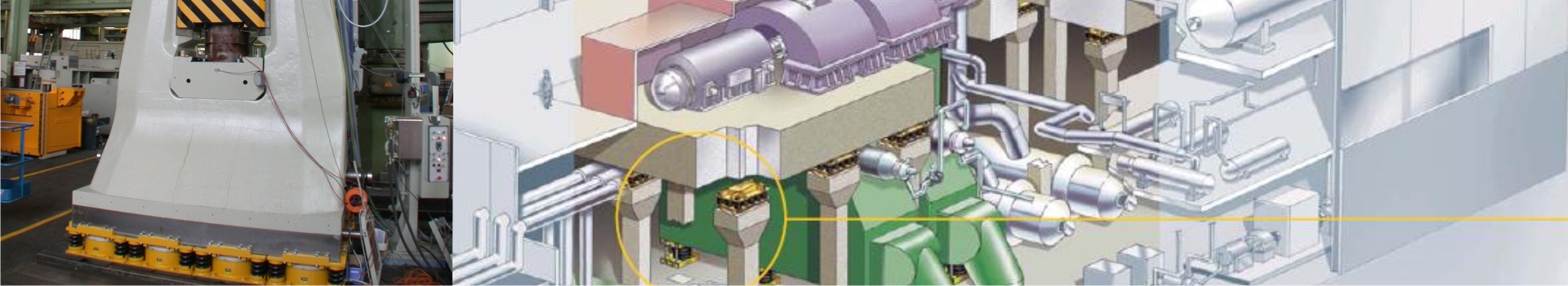

Test stands and other testing equipment are world-wide used to study the dynamic behaviour of parts and systems. Tests are performed with periodic, shock or random excitation. Since test stands are usually located near sensitive measuring and analysing equipment, vibration isolation is extremely important.

A typical example of such a test stand is a shaking table used for:

- simulations of multi-axle dynamic loads

- testing and verifying the functional safety of e.g. components for the car- or aircraft industry.

Other applications for test stands are, for example:

- axle testing

- engine testing

- testing of hydraulic systems

The type of vibration excitation is the basic factor for the design of the elastic support system. When using GERB spring units, which isolate both structure-borne noise and vibrations, an accurate calculation of horizontal and vertical natural frequencies of the test stand or equipment is possible. Vertical natural frequencies as low as 1 Hz can be achieved, with the horizontal and rocking frequencies even lower. GERB spring units are often combined with Viscodampers® to quickly reduce shock excited amplitudes and to avoid a major amplification of periodically excited amplitudes when operating near the resonance frequencies. The most important advantages of the elastic support of test stands and other testing equipment are:

- Little or no transmission of vibration and structure-borne noise into the surroundings,

- Protection of operators and other personnel from vibrations,

- Optimal balance between vibration excitation and test stand capabilities,

- Simple installation of both, the GERB spring units and the test stand,

- Easy alignment and adjustment of the test stand,

- Foundation costs are reduced, e.g. elements may be installed directly below a mounting plate.

Also precision machine tools like Roll Grinders, Machining Centres, 3-D Measuring Machines, Microscopes or Test Equipment, located typically in the middle of a plant, are often sensitive to vibrations, excited somewhere in the surroundings.

Experience has shown that measures like joints or trenches will provide no or at least only insufficient vibration control. Very efficient is, on the other hand, the so called passive vibration isolation, i.e. the elastic support of the equipment itself, typically mounted on concrete slabs or steel plates, to increase their torsional stability and operational accuracy. The more flexible the elastic elements are the better is the vibration control effect. Additionally GERB spring units are in these cases usually combined with Viscodampers®. The spring supported foundation sits in most cases below floor level.

If a specifically high vibration control becomes necessary, vibration measurements at the future location of the precision equipment is recommended in advance while the other machines causing the vibrations are in operation. Based on the results of such measurements spring elements and Viscodampers® can be selected in an optimal way.

Contact us for more information.