Room silencing, vibration reduction, vibration and noise measurements

Room silencing, vibration reduction, vibration and noise measurements

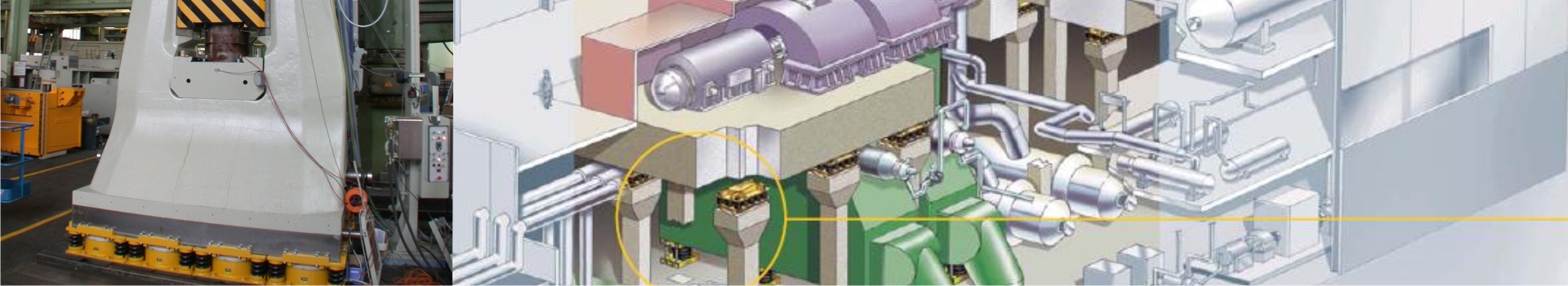

Large gas and diesel engines are used for many purposes, i.e. trains, ships and for local power generation. In all cases, foundations for these engines must be both economical and effective. Elastic support of this equipment meets these requirements.

During operation, some of the oscillating forces and moments generated by the engine are balanced internally; remaining forces and moments are transmitted into the foundation.

Normally, both the engine and generator are arranged on a common rigid foundation. In case of small equipment this would be usually a steel frame. Larger generators usually have a concrete foundation that is often provided to balance the dynamic forces of the engine with a corresponding mass resp. to channel the dynamic and static forces into the subsoil or substructure. However, even a massive concrete foundation will not prevent the transmission of dynamic forces into the subsoil and therefore effecting the building and its surroundings. This can create vibration problems.

While settlement problems can be solved with an expensive pile foundation, the transmission of disturbing dynamic forces can rarely be limited with conventional foundation methods. Any subsequent alteration of the foundation is expensive, and in any case this requires tremendous work and a shut-down of the generator for quite some time.

GERB Spring-Viscodamper® combinations allow the installation of diesel generators in almost any location: whether in the sub-basement of a hotel or on the 30th floor of a high rise building, in a diesel centre or in a Nuclear Power Plant.

Dynamically uncoupling the machine foundation from the substructure – using spring elements and Viscodampers® - provides an excellent solution to eliminate vibration and structure-borne noise at the source and to protect the immediate vicinity and neighbouring buildings.

The GERB system provides the following advantages:

- The machine foundation is dynamically uncoupled from the surroundings with high isolation efficiency (up to 98%)

- The transmission of structure-borne noise is virtually eliminated

- The foundation mass and therefore the foundation size can be substantially decreased.

- Ground water problems can be avoided with a foundation that does not require a deep pit.

- Spring elements can be easily adjusted in case of substructure settlement.

- The size of the diesel generator building can be reduced.

- The elastic support system can be designed to protect gas and diesel generators against damage in seismic zones.

Contact us for more information.